Description

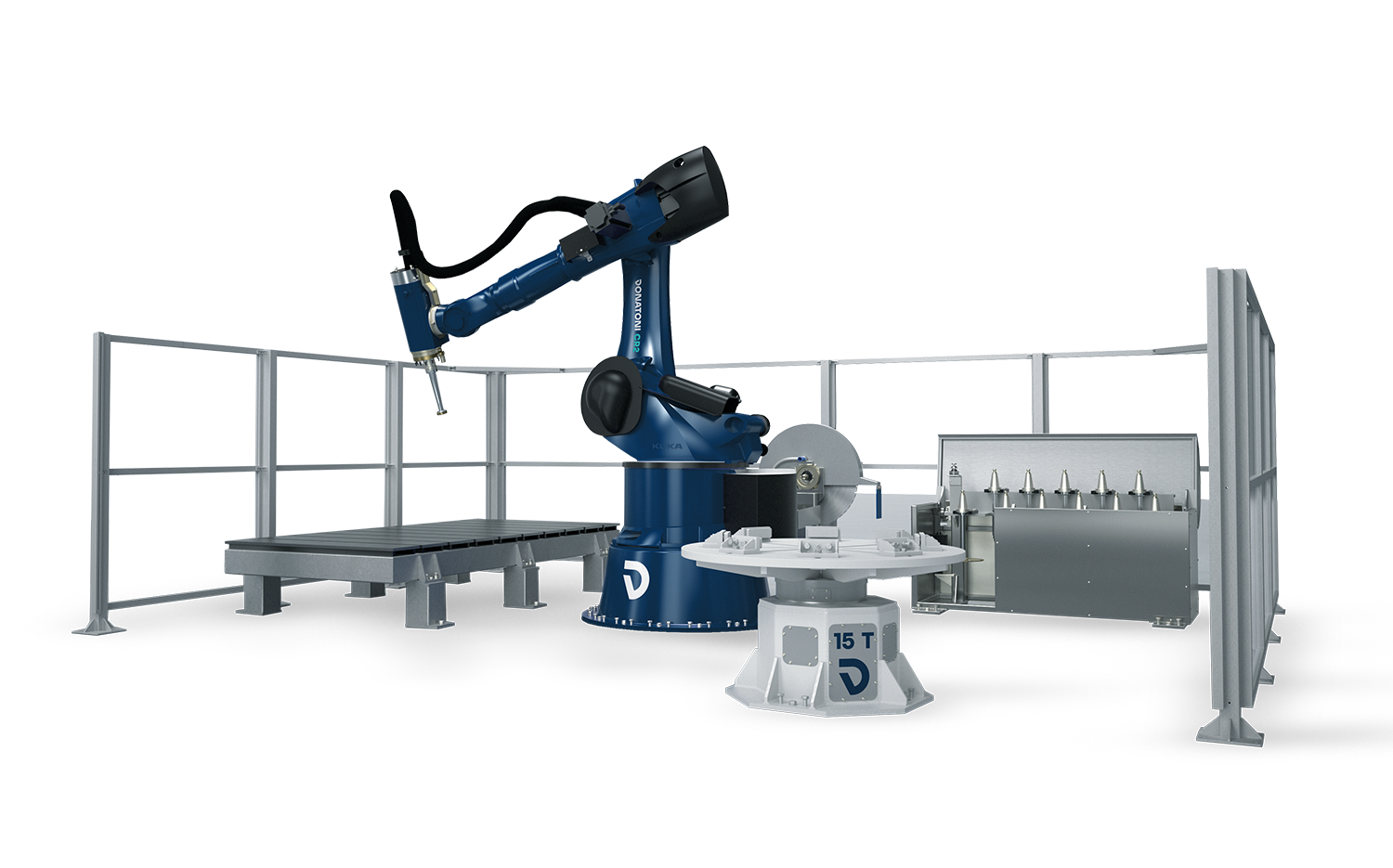

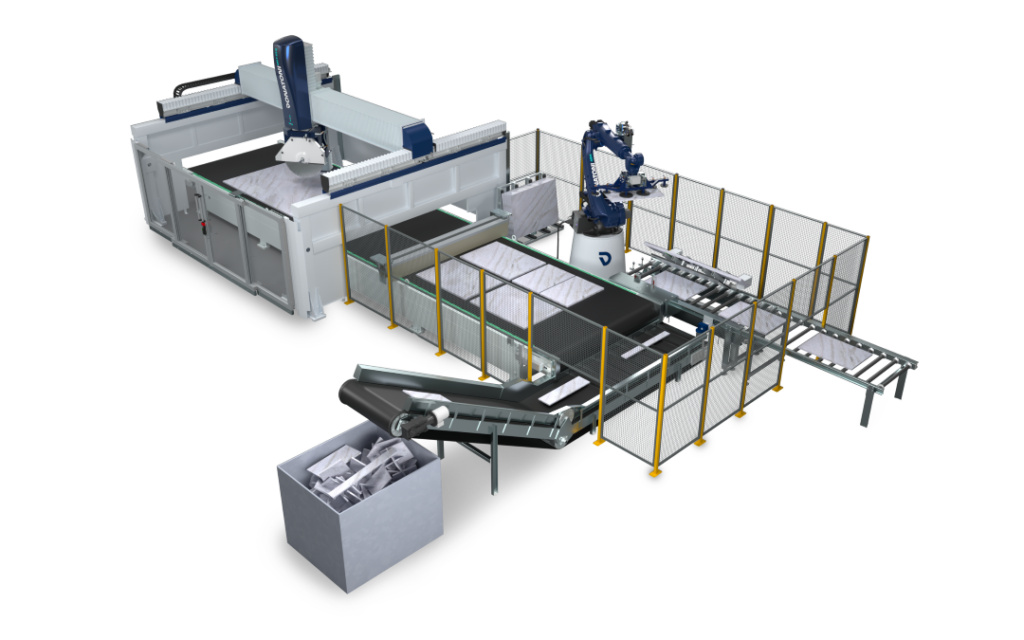

Next-generation robotised production systems

The Donatoni CR2 is a new-generation CNC robotised production system with 6/7/8 interpolated axes, designed to be a highly flexible tool for the production of elements and objects in stone material up to 3300 mm high. This machine allows a ’wide range of work processes to be performed, like cutting, milling, drilling and simple or complex shaping.

The system is fully customisable both in terms of layout and optional accessories, such as the ISO50 automatic tool and blade changer, the interpolated rotating table, the interpolated horizontal lathe, the aluminium top platform, and the wooden top benches.