Description

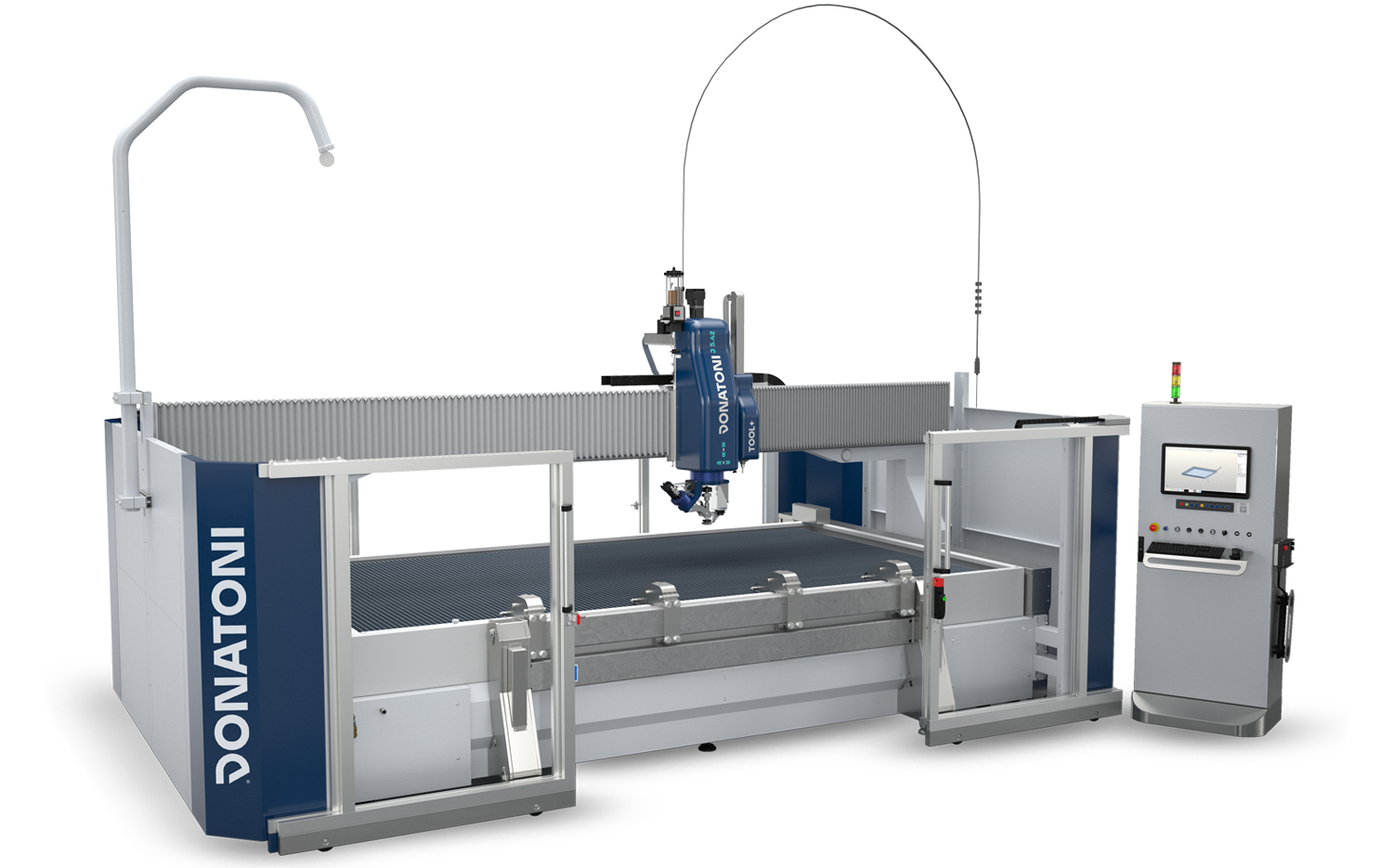

The DONATONI J5.42 is the newest Waterjet cutting centre, designed and developed by DONATONI, to meet the needs of customers looking for a reliable and easy-to-operate waterjet cutting system for processing different materials.

The DONATONI J5.42 is the newest Waterjet cutting centre, designed and developed by DONATONI, to meet the needs of customers looking for a reliable and easy-to-operate waterjet cutting system for processing different materials.

Made entirely in Italy and at the forefront of technology, DONATONI J5.42 allows for various types of cuts (longitudinal, transversal, oblique, inclined, curvilinear, elliptical), as well as milling and lowering (with the addition of TOOL+), and finally, through holes and inlays.

The customer is our top priority. The DONATONI J5.42 can be customized according to the needs and specific requirements requested by our customers. Through a special rotary joint, it is possible to enable the infinite rotation of the “C” axis without limitations imposed by cables or tubes.

The centrepiece of the DONATONI J5.42 is the cutting head, an innovative 5-axis, compact and powerful unit equipped with state-of-the-art technology. It has a C-axis with endless rotation and a nozzle tilt axis between +/- 60°, with a built-in reduction unit that allows high-pressure piping to pass through.

Multiple Solutions for Top Performance

Donatoni offers a complete range of high-pressure systems for waterjet cutting, designed to meet different needs in terms of energy saving, productivity, and efficiency. Each system is engineered to ensure high performance, reliability, and optimization of operating costs.

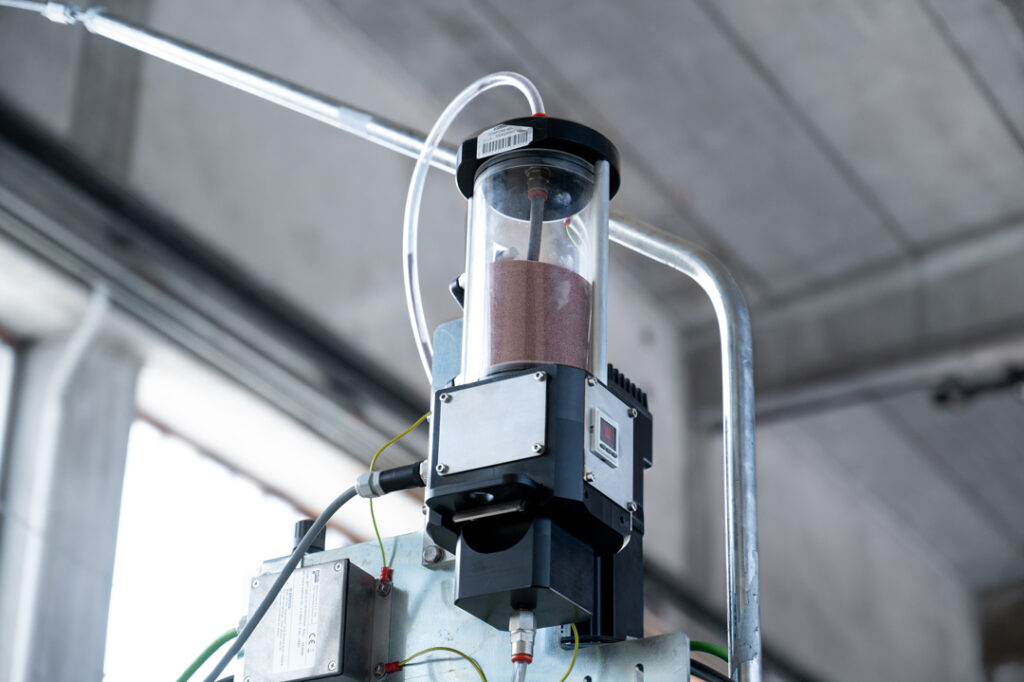

The powerful abrasive agent feeder facilitates the feeding of abrasive into the machine, allowing the operator to load new material into the first tank without interrupting any machine operation. It consists of two tanks, the first one with a large capacity of about 200 litres, while the second operates under pressure. The abrasive feeder is equipped with an adjusting system managed automatically by the machine control.

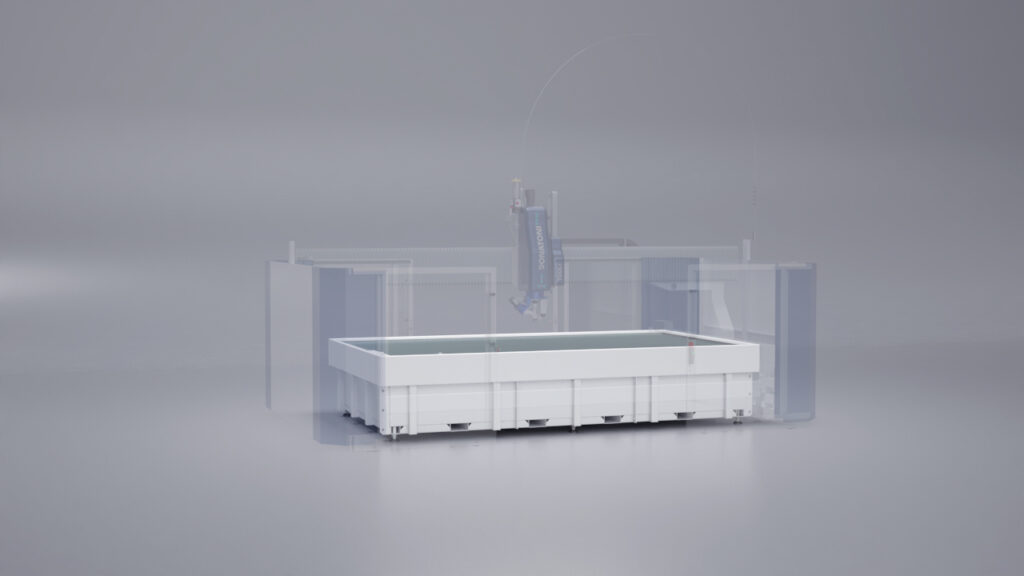

The tank, made entirely of steel, has a working table made of galvanized blades for the Waterjet cutting, on which the material to be processed is placed. The table is easily removable, simplifying cleaning operations. Maintenance and cleaning are facilitated by the fact that it is possible to remove the blade table in one step. The tank is galvanized and painted on the outside to ensure greater corrosion resistance. In addition, the tank is equipped with adjustable feet and the connections for the draining system.

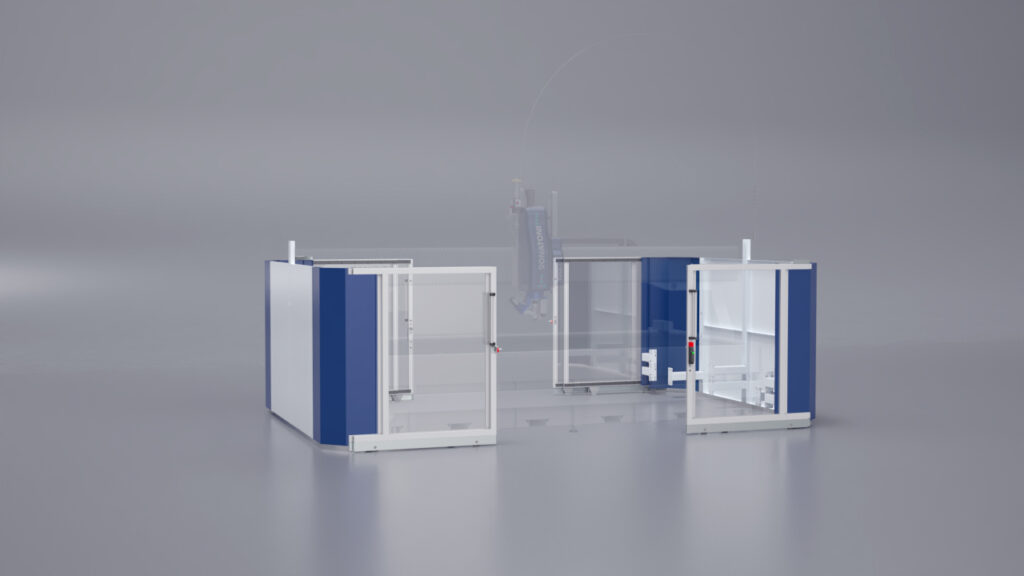

The DONATONI J5.42 is available with two different versions of perimeter safety guards, optical or physical barriers (with TOOL+ physical barriers are mandatory), depending on the customer’s needs. Both solutions offer maximum visibility, small dimensions and high safety. The version with sliding doors is equipped with a front closure with 2+2 wings.

Everything within reach. The control panel is the basic tool for using and programming the machine, so it must be as simple and intuitive as possible. This is a monitor incorporated into the QE equipped with a large 21″ touch-screen. Operators can either program operations in automatic or manage them in manual, as required.

The cross-shaped laser is installed alongside the head unit. This tool is essential to detect slab perimeters, determine the origin points during processing by CAD/CAM programs, and support additional software for the creation of profiles and shapes template models.

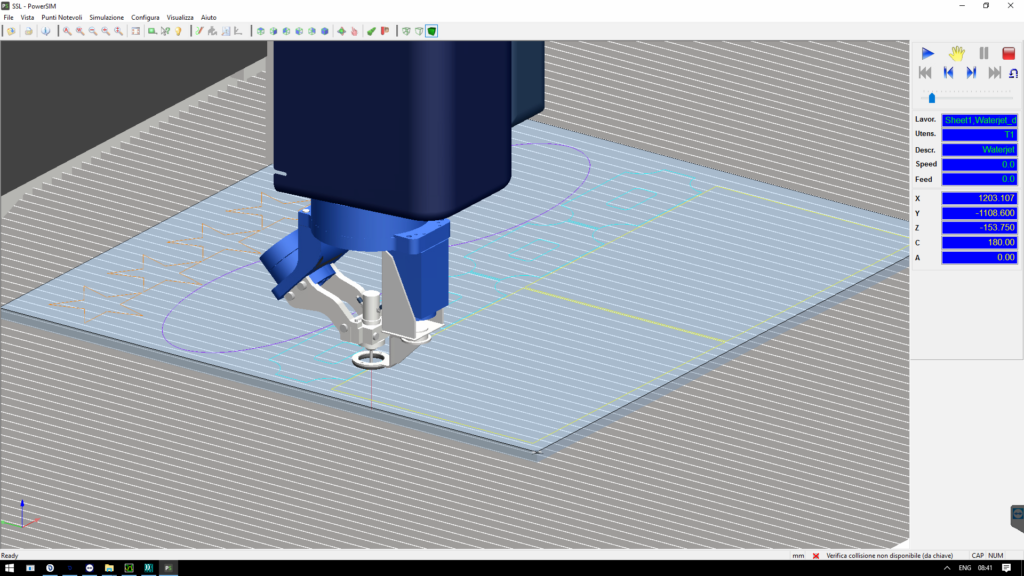

EasyJET is a CAD/CAM software designed for CNC waterjet machining. With a wide range of functions, it makes every aspect of waterjet machining easier and more efficient. Its main features include the import of files in different formats such as DXF, IGES, STL, PNT and RHINO, allowing work with parametric models. It can perform 3-, 4- and 5-axis machining.

The DONATONI J5.42 is the newest Waterjet cutting centre, designed and developed by DONATONI, to meet the needs of customers looking for a reliable and easy-to-operate waterjet cutting system for processing different materials.

| Number of interpolated axes | N° | |

| Carriage stroke X axis | mm | |

| Maximum carriage speed (X axis) | m / min | |

| Bridge stroke Y axis | mm | |

| Maximum bridge speed (Y axis) | m/min | |

| Vertical stroke Z axis | mm | |

| Maximum head speed (Z axis) | m / min | |

| Blade-carrying head rotation (C axis) | degrees | |

| Waterjet head tilting movement (axis A) | degrees | |

| Maximum slab dimensions | mm | |

| Work table load capacity | kg | |

| Abrasive tank capacity | l | |

| Water consumption (3 bar) | l/min | |

| Air Consumption (7 bar) | Nl / min | 100 |

| Standard electric voltage | V/Hz | |

| Total installed power (without optional) | kW | |

| Total weight (approx.) | kg |

Error: Contact form not found.