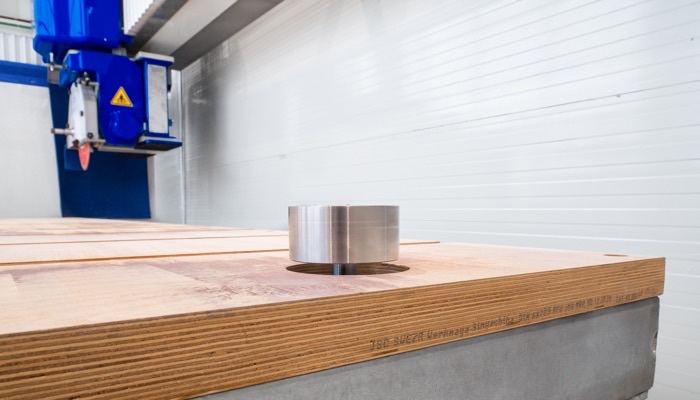

Parametrix

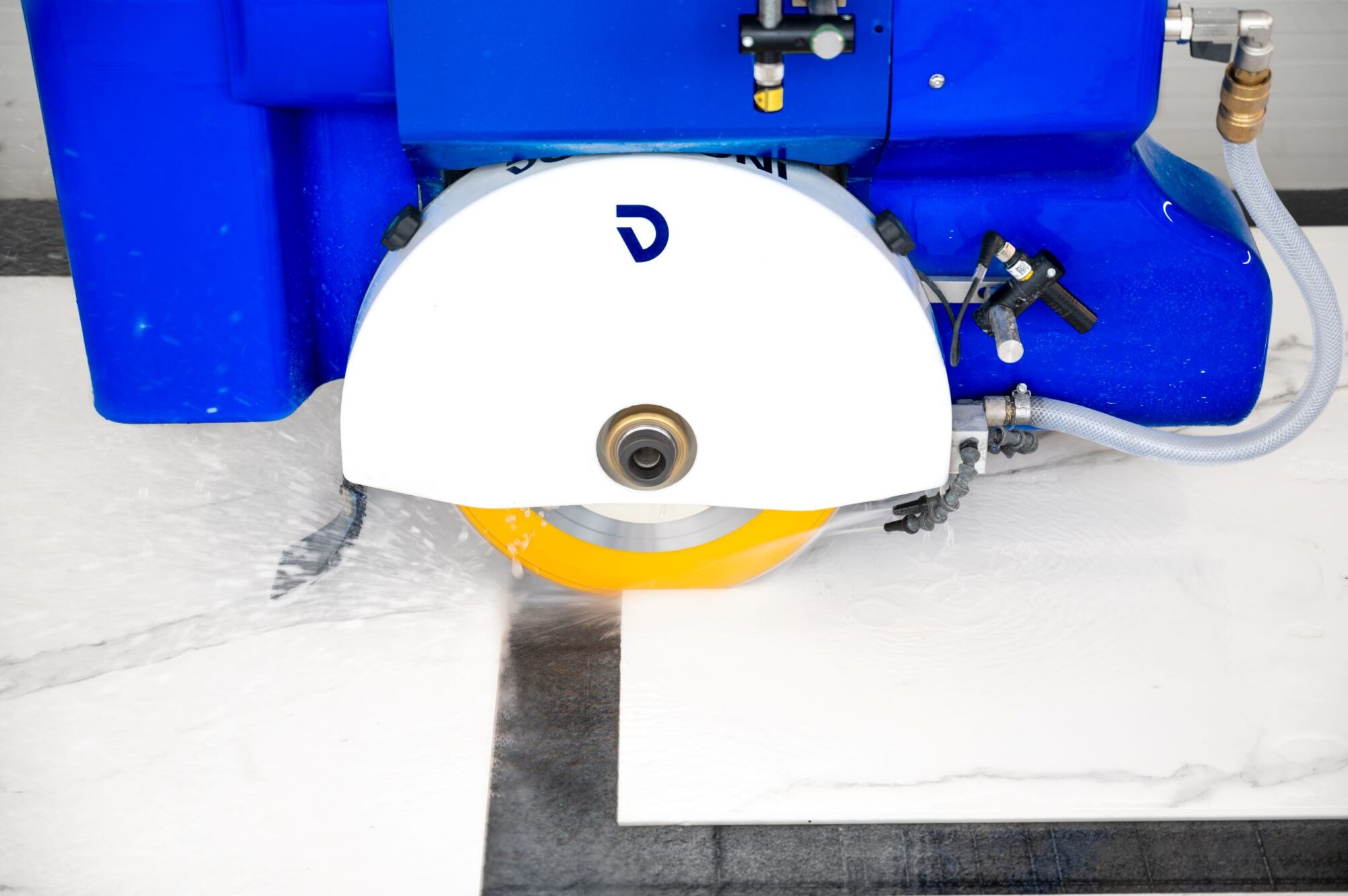

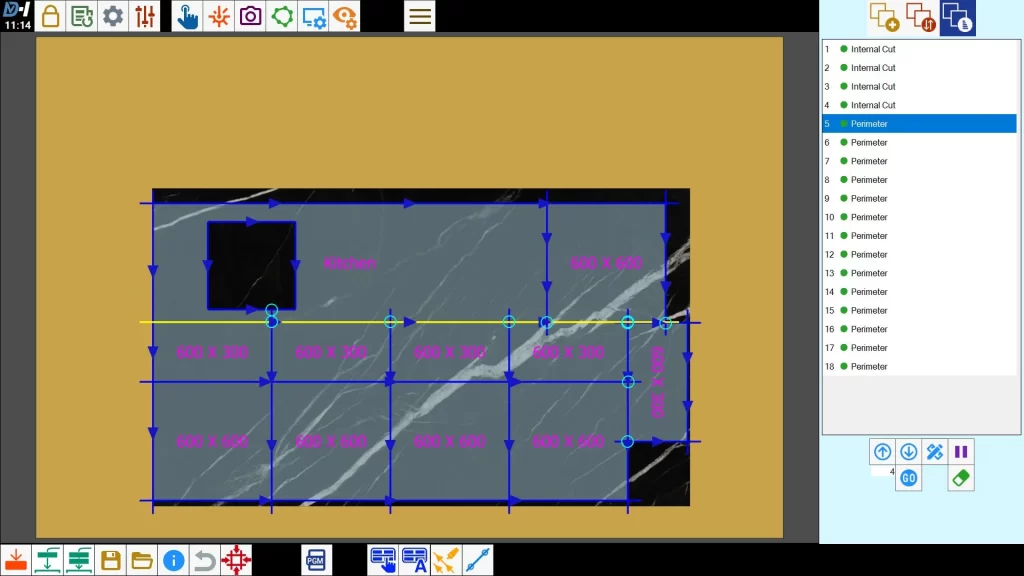

Parametrix is the simple and intuitive Software developed by Donatoni Macchine and designed to optimise the management of cuts of variously-shaped pieces on a slab.

It enables work processes involving cuts with discs, milling cutters and drills, the insertion of straight and curved forms and shapes that have been pre-set or imported from DXF files, and the optimisation of processing times and slab surfaces. Based on the available surface it is possible to set the pieces arrangement and cut sequences. In the software are included anti-collision functions, manual and automatic nesting, production statistics management. Parametrix can be combined with Photoslab and Move-System.