Taking care of every surface

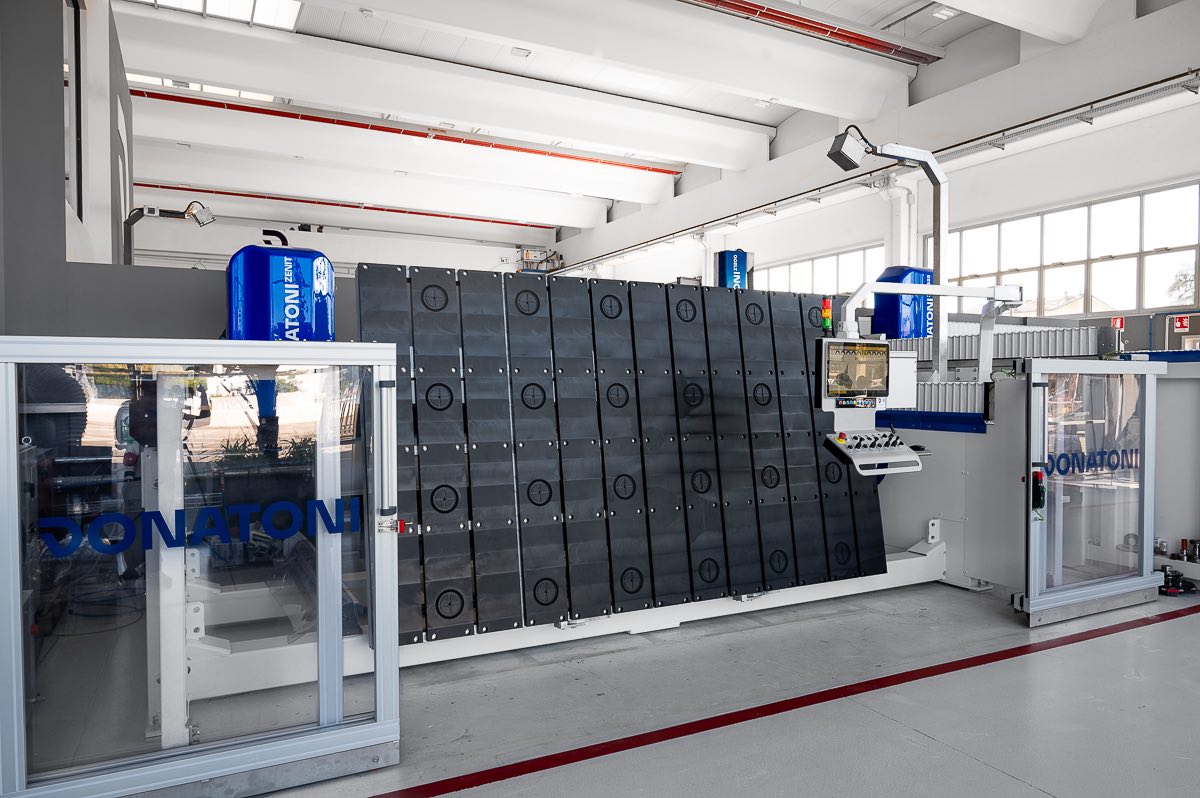

CNC single-head polishing/calibrating machine

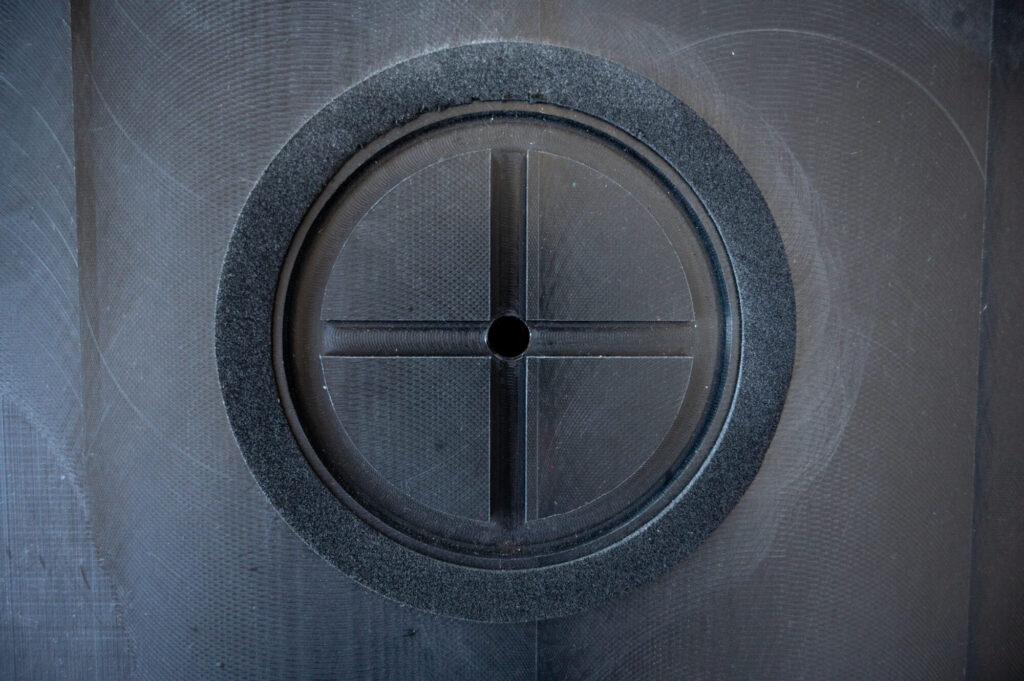

The DONATONI ZENIT is a single-head CNC polishing/calibrating machine with 3 interpolated axes, with 8-position automatic tool changer + 1 calibrating tool, for the treatment of marble and artificial stone surfaces.

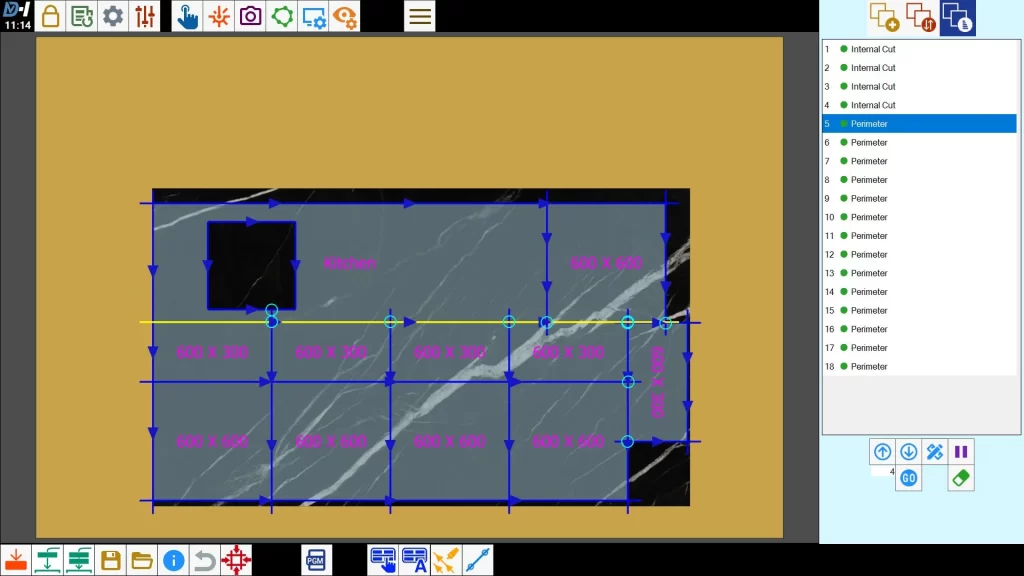

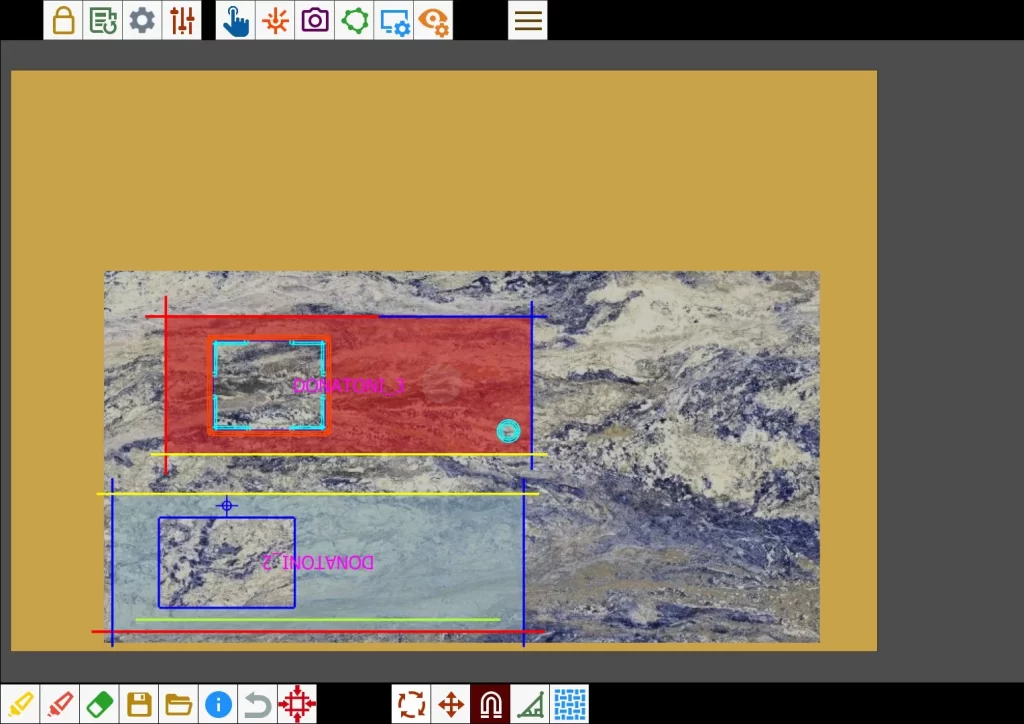

Complete treatment

Calibrating, polishing, brushing, as well as drilling, engraving, and making straight and curvilinear cuts with incremental passes by means of diamond milling tools. It is an extremely flexible machine, ideal for those who need a complete equipment to treat even particularly delicate surfaces or to finish mosaics or inlays.

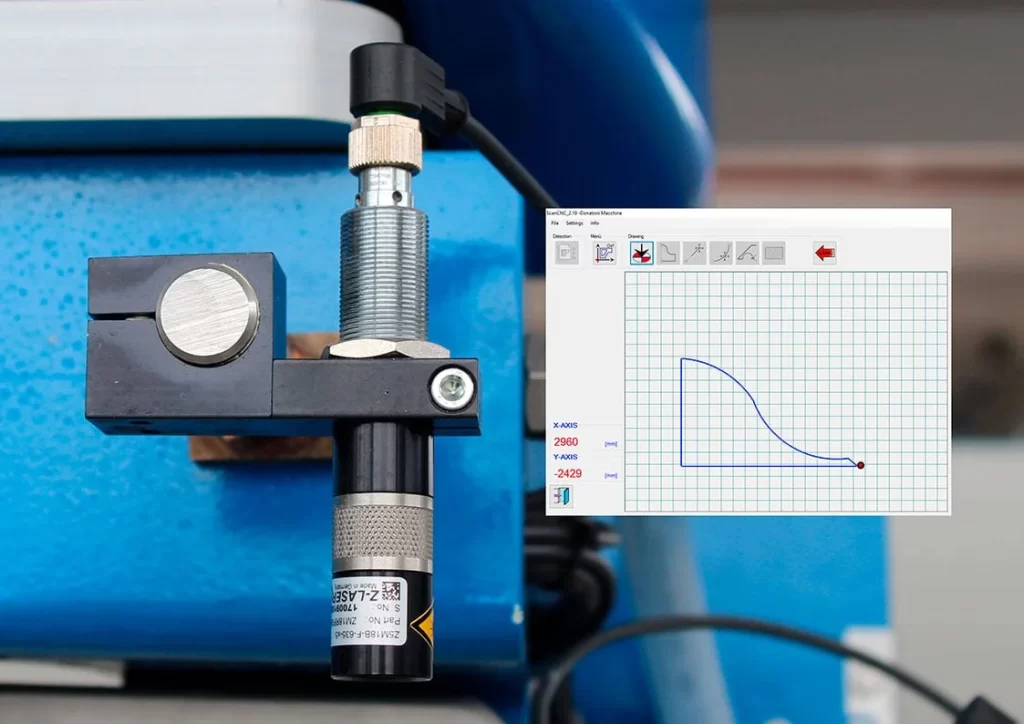

Working without limits

Its strength lies in the dual-control system of pneumatic and mechanical handling of the polishing and calibrating tool; the result is an extreme precision with excellent performances on any material.